CLIENT NEED

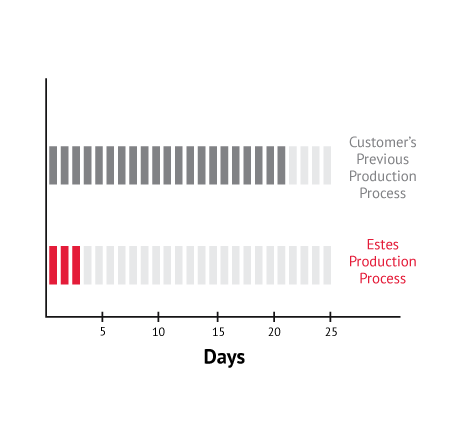

While working with a previous fabrication partner, the client was managing the production process themselves – taking three weeks to shuttle parts from one subcontractor to another and wasting precious time that could have been spent on revenue-generating business operations. Raw materials alone cost more than $24 per final unit produced. Continuing to manage production in this manner would inhibit the client’s growth.

SOLUTION

The client visited the Estes Accelerator shop and watched as their design was brought to life by the automated cell. Estes was able to create a new prototype that was cheaper to produce ($24 final unit cost) and of the same quality as the original product. The client was blown away by the time saved with the new design as well: production lead-time went from three weeks to three days. Plus, final product looked better than the previous design.

RESULT

The client now delivers a better product at a lower cost within a streamlined production process. While Estes produces quality products for the client’s customers, the client can spend less time managing the process and more time growing their business.