There are two major laser cutting systems on the market today used in sheet metal fabrication: CO2 and fiber laser cutting technology. With much discussion in manufacturing circles on which cutting technology is the better method, there are several notable differences between CO2 and fiber laser cutting technology when it comes to their capabilities and, more importantly, their performance when cutting certain materials and thicknesses. This quick primer will help you be more informed on both methods so you can better understand the mechanics of your sheet metal fabrication project and effectively utilize the benefits of both laser cutting technologies.

What is a CO2 Laser?

CO2 (carbon dioxide) lasers function by passing electricity through a glass tube filled with a mixture of carbon dioxide, nitrogen, helium, and hydrogen gas and into a mirror, which directs the newly-created light beam into the laser cutting head (MellowPine). These lasers have been around since the 1960s and are the most widely used laser systems for material cutting. See CO2 laser cutting process in video below:

Pros of CO2 Lasers

CO2 lasers have many advantageous characteristics. Because of their high market saturation, they are well-developed and highly reliable. They also offer faster initial piercing of the material and operate more efficiently on thicker plates (greater than 1/3 – ½ inch) compared to a fiber laser. This means they are more flexible overall in their ability to cut different thicknesses of sheet and plate metal and can be used for a wider variety of applications.

Cons of CO2 Lasers

On the other hand, CO2 lasers are not generally as energy efficient. They average about 10-15% energy conversion (All3dp.com) and thus require more power to operate, driving up total project costs. They also require regular maintenance, part replacement, and cleaning, which means more downtime.

What is a Fiber Laser?

Fiber lasers get their name because they use fiber optics to deliver a powerful laser with little energy loss to the cutting head. They are relatively new compared to CO2 lasers but are becoming faster and more efficient as they are continually developed. See fiber laser cutting process in video below:

Pros of Fiber Lasers

Although fiber lasers are still growing in power and application, they have many advantages over their CO2 counterparts. They operate at roughly a quarter of the energy required to make the same cut with a CO2 laser. This is because their energy conversion is much better; they use 35-50% of their power supply in the laser (All3dp.com). They also are virtually maintenance-free, so downtime is greatly reduced, meaning higher overall throughput. As innovation continues in the design of fiber lasers, they are becoming less expensive and more powerful.

Cons of Fiber Lasers

Fiber lasers are not always the best choice, however. While not impossible, it is more difficult to cut through thick pieces of metal with a fiber laser, and its efficiency greatly decreases in these situations. They are not as flexible as CO2 lasers in their ability to adapt to all thicknesses of materials. In addition to this, cosmetically critical vinyl coated stainless steel products can be challenging to cut.

Which laser cutting technology is best for your project?

When determining which laser to use for your project, there are several factors to take into consideration.

Type of material

Some metals, such as aluminum, are highly reflective and therefore do not absorb a CO2 laser beam very well. Still others, such as copper and brass, are so reflective that they are practically impossible to cut with a CO2 laser. In these applications, a fiber laser would be the better choice as its wavelength is more readily absorbed. Carbon steel and stainless steel can be easily cut with either laser method.

Material thickness

As mentioned earlier, the two types of lasers perform differently depending on the thickness of the material being cut. CO2 lasers have a longer wavelength than fiber lasers, and so they work better for thicker materials. “The long-wavelength works like a long sharp saw while the short wavelength works like a really sharp needle or drill. The really long sharp saw will be better at cutting thick stuff while a really sharp needle/drill will work better at piercing through thin stuff faster,” (Senfeng). The fiber laser works much better for thinner materials than a CO2 laser.

Finished edge

If you need a clean edge, CO2 is the way to go. Surface edges are much smoother following CO2 laser cutting than the edges a fiber laser leaves. However, other finishing and deburring methods can be performed on fiber-laser-cut parts to achieve a smooth edge.

Laser Cutting at Estes

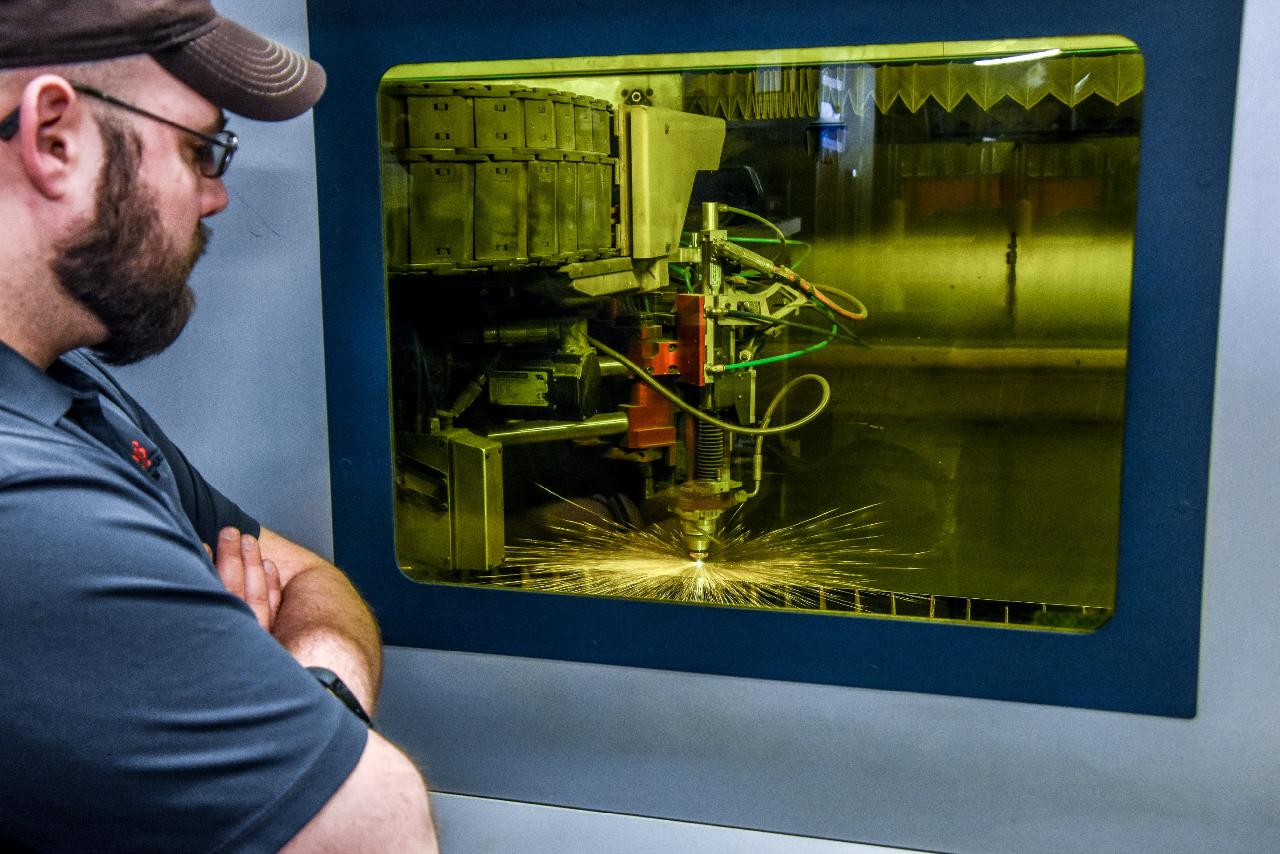

Here at Estes, we have both CO2 and fiber laser technology in our plant. Our Estes Accelerator prototype department utilizes the Salvagnini L2 CO2 Laser. It is better suited for prototyping because it can better cut a range of thicknesses and easily cuts our most popular metals. Because it is used for smaller prototype projects and not large-scale production, the lower efficiency does not cause problems.

Our main production setup includes  the Salvagnini L5 High Dynamics Fiber Laser which also plays a critical role in our Estes Max Velocity automated fabrication cell. This fiber laser is perfect for continuous production because it is much more efficient for high volume jobs and requires little to no maintenance, increasing overall throughput where it matters. The L5 also permits quick changeover and facilitates nesting, with all these capabilities culminating in a machine that reduces costs while increasing speed on our customers’ sheet metal fabrication projects.

the Salvagnini L5 High Dynamics Fiber Laser which also plays a critical role in our Estes Max Velocity automated fabrication cell. This fiber laser is perfect for continuous production because it is much more efficient for high volume jobs and requires little to no maintenance, increasing overall throughput where it matters. The L5 also permits quick changeover and facilitates nesting, with all these capabilities culminating in a machine that reduces costs while increasing speed on our customers’ sheet metal fabrication projects.

Because we maintain both kinds of lasers in our robust list of equipment, Estes is equipped to handle any laser cutting need your sheet metal fabrication project or prototype may have. Contact us today to get more information on how we can provide what you need!