Estes Philosophy: Continuous Improvement

Over the past several months, we’ve shared three pillars of our philosophy, innovative thinking, people of high character and state-of-the-art technology. As a reminder, our philosophy at Estes Design and Manufacturing is to profitably produce fabricated metal products with a level of service and quality preferred by the customer. The fourth pillar of our philosophy is continuous improvement, which will be the focus of this final blog.

At Estes, we focus on three main areas of continuous improvement:

- Technology and Automation

- Unique Service Offerings

- Lean Manufacturing

Continuous improvement achieved through technology and automation

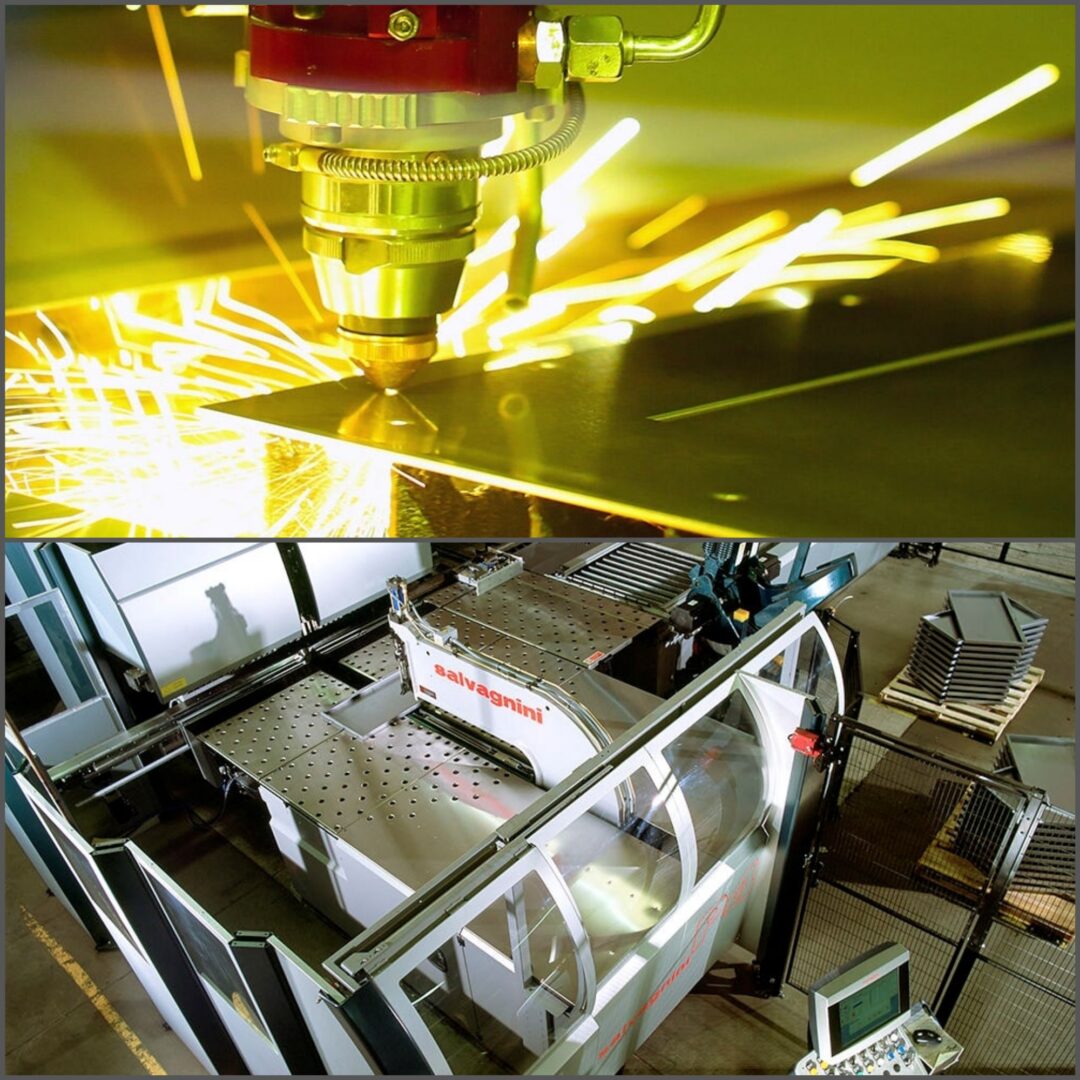

In the late 1990s, we shifted our focus at Estes Design and Manufacturing to technology and automation in an effort to differentiate ourselves from our competitors. Since then, we’ve tried to continuously improve our equipment to stay on the leading edge and bring the benefits of the latest technology to bear on our customers’ products. In the world of sheet metal fabrication, speed and quality mean everything to our customers, and high levels of automation maximize uptime and improve part accuracy and consistency. To learn more about our state-of-the-art equipment take a virtual tour.

Continuous improvement produces unique service offerings

At Estes, continuous improvement means looking for ways to add additional value for our customers. Examples of this continuous improvement in action can be found in the addition of two new services:

- Understanding that our customers need access to prototyping services in a pinch, we launched Estes Express Prototyping, a prototype shop with dedicated equipment and personnel that’s geared to meet our customers’ speed-to-market needs.

- Observing the growth of laser welding in the automotive industry, we saw an opportunity to adopt this technology to sheet metal fabricating. After applying expertise and ingenuity, Estes perfected a 3D laser welding offering that is between 10x to 40x faster than traditional welding and requires no post weld clean-up.

Continuous improvement promoted through lean manufacturing

The final focus of our continuous improvement is lean manufacturing. At Estes, lean manufacturing places an emphasis on the services we provide to our customers as the sole purpose of the company, and any activities that do not add value to the customer are waste. Two factors of lean manufacturing that relate to continuous improvement are:

- Improvement is always both possible and necessary, through Kaizen.

- Employees are empowered and challenged to continuously improve and eliminate waste rather than just put in their time.

The result is an organization full of individuals constantly looking for a better way to do things. Those improvements incrementally enable us to reduce lead-times, improve quality, and meet delivery deadlines consistently for our customers at a competitive price.

Estes Design and Manufacturing: Let us help you find the solution for your next project

As a company who has been in business for over 40 years, we have a proven history of completing projects of varying size on time and under budget. Let us show you how we can put the four pillars of our philosophy at work for you. Contact us today through our website or call us at (317) 899-2203 for your next project.