At Estes Design and Manufacturing, we’ve invested in the highest-quality technology available for our customers’ metal fabrication needs – machines whose unique capabilities benefit our customers through cost reduction, improved quality, and reduced lead-times. We strive to proactively and constantly monitor our equipment and standards to better serve our customers, and we have recently added two new pieces of technology to our robust list of equipment – a new Salvagnini S4Xe punching and shearing system and a Trumpf TruBend 5085 X press brake.

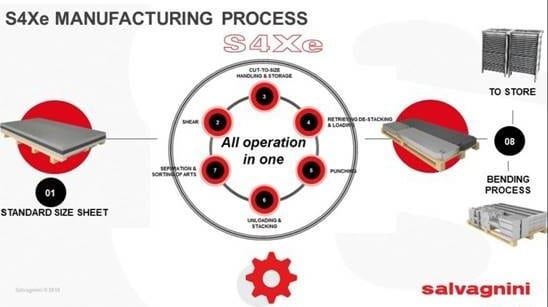

The Salvagnini S4Xe Punching and Shearing System

The new S4 we announced last month is now installed and fully operational. This new machine is a fully integrated and automatic punching and shearing center that delivers high-quality parts and provides unmatched throughput. It can process single parts or multiple nests while reducing waste and inefficiencies. Operations that would normally require manual labor – such as loading, unloading, stacking, separating, and sorting – are all fully automated at the S4. This new S4 ensures responsiveness and efficiency while operating with different production strategies, allowing it to pair perfectly with our just-in-time inventory management services.

How It Works

Our Salvagnini MV Warehouse brings raw material to the shearing/punching center when directed, and sheets are loaded unattended. The machine punches features into the blank and then shears the perimeter of the blank to separate it from the sheet. The punched parts are then automatically unloaded onto a tray to be temporarily stored in the Salvagnini MV Warehouse until they are ready for forming operations. The Salvagnini S4 is capable of running unmanned, allowing it to run lights-out over weekends when tight deadlines are necessary.

Benefits:

- Provides extreme accuracy and repeatability to produce high-quality parts

- Features fully automatic punching, shearing, and separating operations as well as automatic material feeding and sorting cycles to reduce costs

- Delivers high productivity and process efficiency to ensure on-time delivery

The Trumpf TruBend 5085 X Press Brake

This new press brake can achieve complex bends in both thin and thick sheet metal parts. It features thickness-controlled bending sensors that automatically adjust the plunging depth based on the thickness of the part being formed. This allows for high  angle accuracy regardless of the part thickness – without having to reprogram or change setups. Its extended opening height helps to accommodate larger profile projects, and the Trumpf can accommodate a bend length up to 87” and has a bending force limit of 94 tons. Setup times are greatly reduced with the machine’s lightweight click-in tools, cutting down on lead-times and costs. This new Trumpf is an ideal solution for every bending application – no matter how simple or complex the part may be.

angle accuracy regardless of the part thickness – without having to reprogram or change setups. Its extended opening height helps to accommodate larger profile projects, and the Trumpf can accommodate a bend length up to 87” and has a bending force limit of 94 tons. Setup times are greatly reduced with the machine’s lightweight click-in tools, cutting down on lead-times and costs. This new Trumpf is an ideal solution for every bending application – no matter how simple or complex the part may be.

Benefits:

- Allows for off-line programming to increase processing speeds

- Features fast folding/hemming tooling to reduce setup times and costs

- Delivers high accuracy and quality with its 6-axis backgauge and LED part locator aid

- Ensures precise angles across long bends with automatic crowning features

Estes believes that our investment in these machines aligns with our mission to create a competitive advantage for our customers through innovative design, cost savings, and speed. Customer satisfaction is the most important part of our business, and by making upgrades and expanding our offerings, we seek to continue fabricating high-quality parts to a level of satisfaction preferred by our customers. To see how Estes’ state-of-the-art technology can benefit your business, contact us today or request a quote.