Estes Design and Manufacturing is excited to announce the introduction of our new Estes Max Velocity cell! Meeting quality, on-time delivery, and lead-time objectives are some of the biggest challenges companies face when outsourcing their sheet metal products. Max Velocity is Estes’ automated sheet metal fabrication cell designed to address these daily challenges. The automated nature and advanced technology of the cell enable it to provide exceptional quality, shorter lead-times, and improved on-time delivery.

Reduce Your Sheet Metal Fabrication Lead-Times Without Compromising Quality

Estes’ Max Velocity fabrication cell boosts efficiency beyond that of traditional cell manufacturing. Through the use of advanced automation and state-of-the-art equipment, Max Velocity maximizes uptime and improves part accuracy and consistency while reducing lead-times. Our Max Velocity Automated Cell serves as the cornerstone of our lean manufacturing initiatives, taking efficiency to the next level.

Max Velocity Brings Estes’ Customers:

- Faster fabrication and shorter lead-times, allowing them to better support their own customers

- Consistent on-time delivery, ensuring their own schedules can be met

- Flexibility in production and order processing, allowing OEMs to switch product manufacturing without having a large inventory

- Reduced inventory, resulting in freed up cash, freed up space, and reduced risk of inventory damage or obsolescence

- Improved quality, which reduces total costs

- Competitive pricing

Estes Max Velocity boosts a 97.2% on-time delivery rate with a ten-day lead-time for products that don’t require painting or finishing—reducing or eliminating the risks for OEMs.

How Max Velocity Works – Powered by Salvagnini

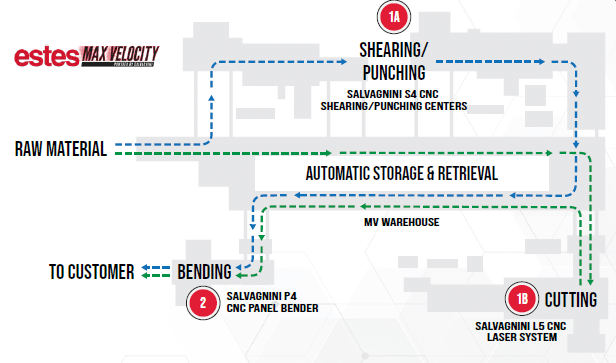

The process starts with the raw material being loaded into the Salvagnini MV Warehouse. Traceability information for each bundle of raw material is recorded and stored in the cell’s software, so it follows the part throughout the fabrication process. Estes’ automated warehouse runs through the cell’s center and automatically delivers materials and parts to and from the four pieces of equipment in the cell: two Salvagnini CNC S4 shearing/punching machines, a Salvagnini CNC L5 fiber laser system, and a Salvagnini CNC panel bender.

Salvagnini MV Warehouse

Our Salvagnini MV Warehouse serves as the backbone to the fully automated Estes Max Velocity cell. This automated technology removes time wasted with material handling, helps increase production output, and ensures faster lead times for our customers.

Salvagnini S4 Punching and Shearing Center

Our Salvagnini S4 machines combine the punching versatility of a turret press with the blanking capabilities of a shear. Not only does the S4’s automation provide around-the-clock activity, but customers also benefit from cost reductions that would otherwise go to pay for labor.

Salvagnini L5 Laser Cutter

Our Salvagnini L5 Laser Cutter allows us to cut sheet metal parts with any geometry, permits quick changeover, and facilitates nesting. These capabilities all culminate in a machine that reduces cost while increasing speed on our customers’ sheet metal fabrication projects.

Salvagnini P4 Panel Bender

Our Salvagnini P4 Panel Bender can achieve high repeatability and tight dimensional tolerances, resulting in a higher quality product. Its advanced capabilities allow it to form extremely complex parts in a single set up while adding efficiency to product throughput.

Is Max Velocity Right for Your Project?

Max Velocity provides the biggest advantage for long-term, light-gauge panel work. Ideal part dimensions for Max Velocity are:

- Up to 11-gauge steel, 14-gauge stainless steel, and 0.150” aluminum

- Up to 62.9” blank width

- Up to 98.4” blank diagonal

- Up to 85.8” bend length

- Up to 6.5” bend height

Reduce your sheet metal fabrication lead-times without compromising quality with Estes Max Velocity automated cell technology. Estes is ready and willing to address all your sheet metal fabrication needs. For any questions or more on how our sheet metal fabricating services can benefit your company, contact our experts today!