As we mentioned in our Material Requirements: Part 1 post on aluminum, identifying what material to use from the beginning is extremely important to Estes. We know in many cases that customers have already clearly documented their material needs, but there are times when the material is uncommon, unclear, or even absent from our customer’s request. In these cases we are happy to help customers identify the best materials to meet their needs. The focus of this post is on stainless steel.

Stainless Steel

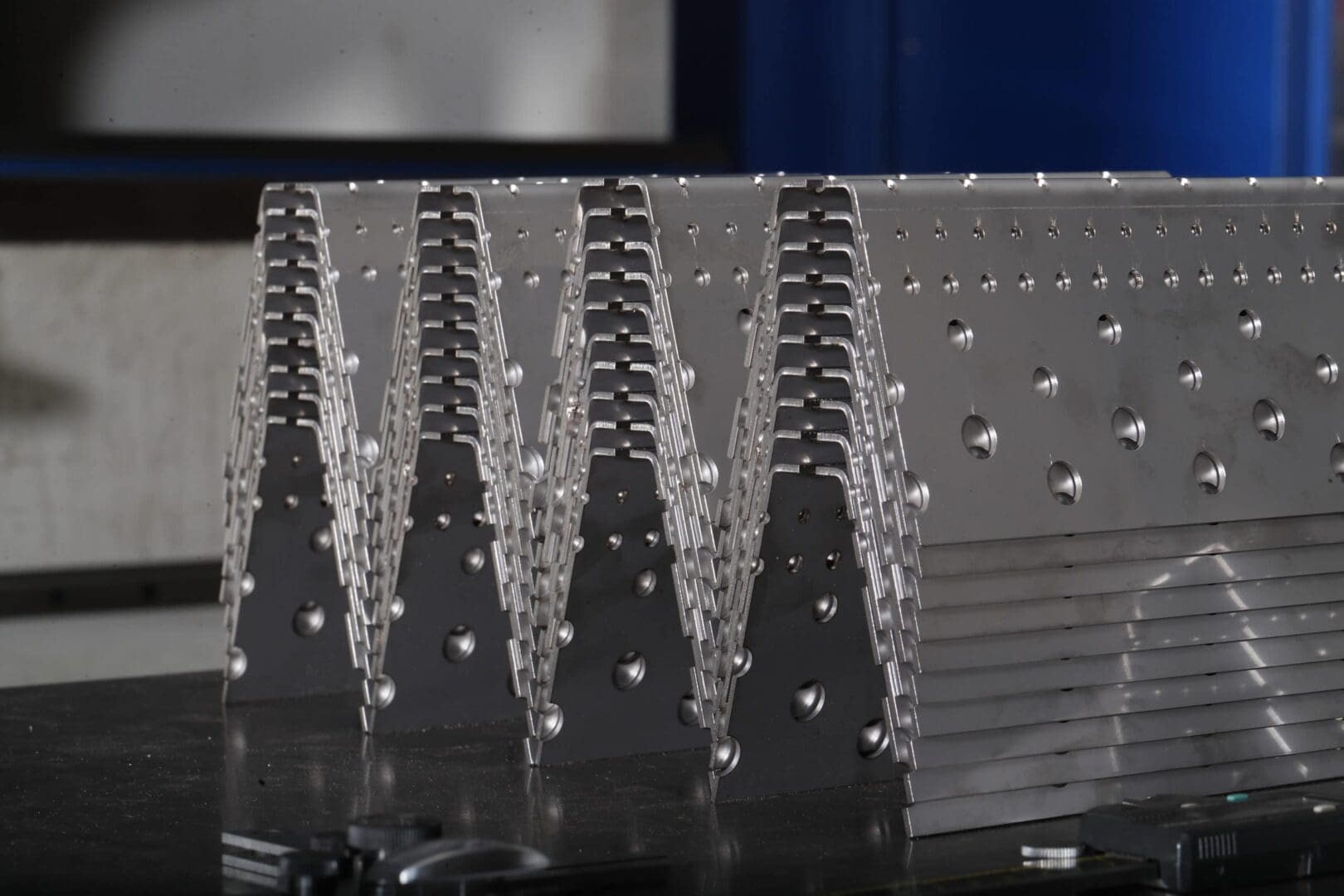

Stainless steel is best run on laser because it is one of the harder materials. There are two primary series of stainless steel used by Estes. Estes uses the 300 series and the 400 series.

300 Series

The 300 series is the most commonly used stainless steel by Estes. It contains very little carbon. The 300 series cannot be heat-treated, and is non-magnetic. It has a very high scrap value.

400 Series

The 400 series has a higher carbon content than the 300 series. It is magnetic making it slightly more prone to rust. If the 400 series is welded, there is a chance of carbon precipitation to cause a problem of rust on the stainless steel.

There is also a wide range of finishes available. The most common to Estes are:

2B Finish

Description: The 2B finish is a standard mill finish. It is gray and uniform looking with no texture at all.

Polished Finishes

Description: The #3 and #4 are brushed finishes that are more expensive. Often, service centers will provide the same product for both finish numbers. To protect the brushed finish, the material is supplied with vinyl protection that adheres to the surface. The vinyl is typically peeled by the end user when the product is in the field.