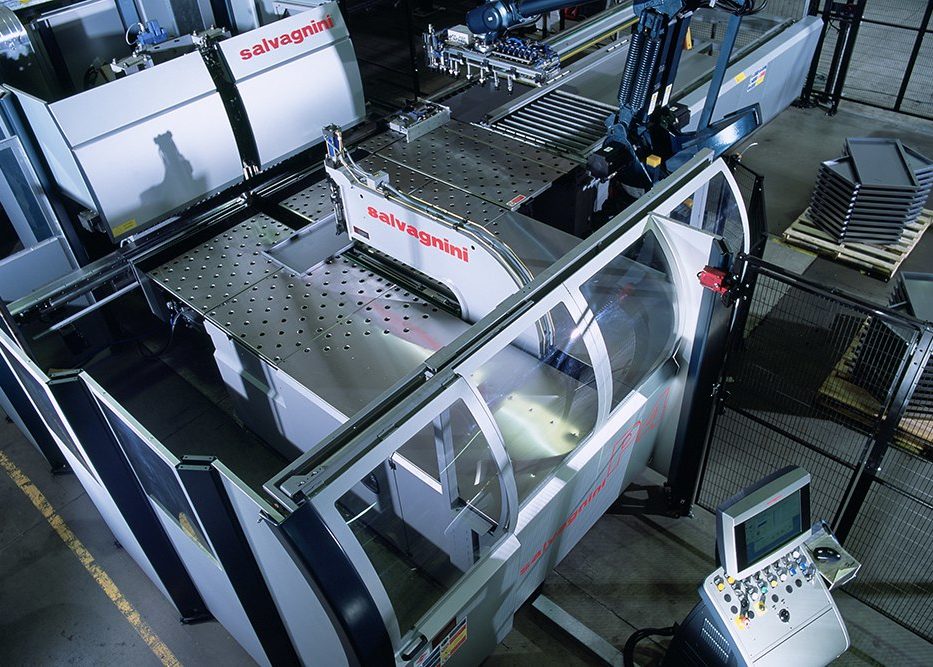

Our Salvagnini CNC P4 Panel Bender is a fully automated machine that bends sheet metal blanks into their final shape. Its advanced capabilities allow it to form extremely complex parts in a single setup. Unlike traditional press brakes that require different tools for different bend configurations, tooling in this panel bender adjusts automatically from bend to bend and part to part.

Flat blanks are automatically presented to the panel bender by the MV Warehouse, and automatic length-adjustment tooling adjusts itself on the fly between bends as the parts run. Forming and rotating of the part are also all fully automated.

Accuracy is unparalleled because of the panel bender’s integrated advanced sensors that measure the blank, including material thickness, for precise placement and bending. The sensors also detect any deformations caused by variations in temperature. The collected data is used to instantly calculate the correct force required to bend the sheet metal. Once completed, the part is automatically unloaded from the machine.