Effective inventory management is all about balance. Carrying too much inventory ties up capital and wastes valuable space. However, carrying too little can result in delays and production inefficiencies.

Economic conditions force many businesses – including OEMs – to reduce the amount of resources invested in inventory. As a result, it is leaning on its supply chain to provide just-in-time delivery for its products.

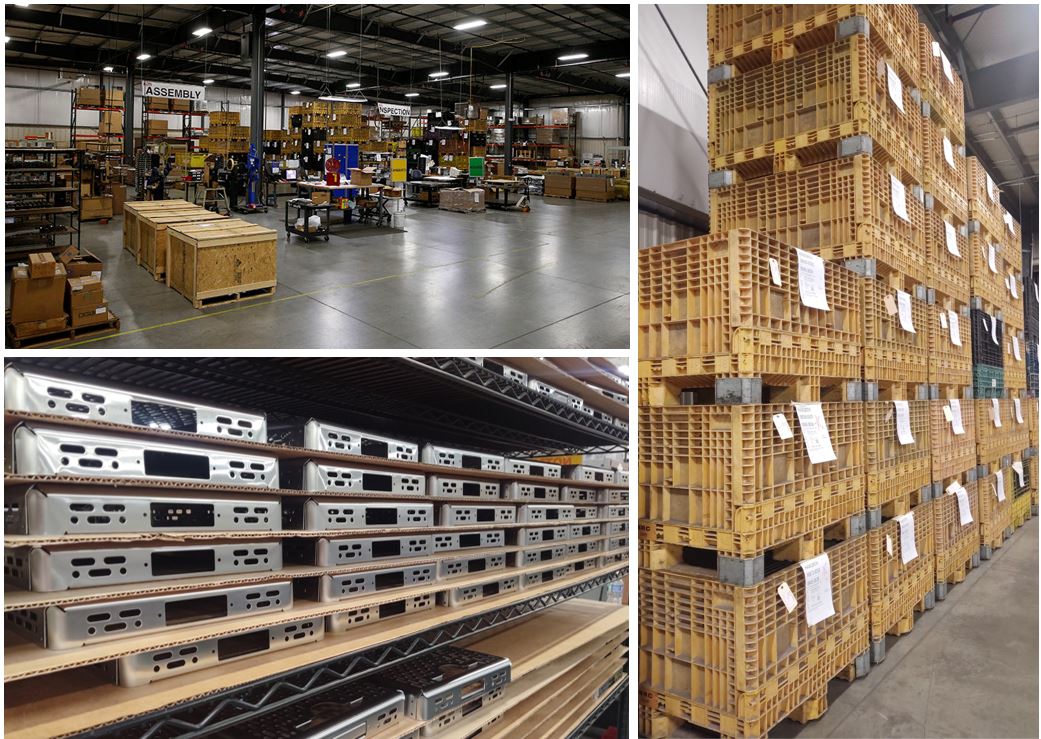

Estes has the experience, tools, and space to be able to accommodate its customers’ inventory management needs. Combining the customer’s forecast and lead-time requirements with Estes’ internal capacity to formulate safety stock levels, the product is ready at the precise time it is needed by the customer.

Contact Estes today to learn more about its supplier-managed inventory system.