The Estes Medical Design and Manufacturing division is an FDA-registered, ISO 13485:2016 certified design and medical manufacturing facility that has been serving the medical industry for more than 30 years.

From conceptual design to prototyping and manufacturing a final product, Estes is your one-stop manufacturer for surgical trays, X-ray shields and screens, sterilization equipment, exam room tables, medical refrigeration and cabinet components/panels, ventilator components, fluid management devices, hospital bed components, operating room equipment, custom latches, wire handles, and other medical devices.

INNOVATIVE | AUTOMATED | COST-EFFECTIVE

Medical Device Production Capabilities

We can design, prototype, and manufacture various sheet metal medical devices and components. We work with stainless steel, aluminum, vinyl-coated metal, powdered-coated, anodized and electric polished metals, and silicon inserts. Here are a few examples of our sheet metal fabrication capabilities:

Surgical Instrument Trays

X-Ray Shields & Screens

Sterilization Cases

Medical Cabinets

Sterilization Components

And More …

Exam room tables, medical refrigeration and cabinet components/panels, ventilator components, fluid management devices, hospital bed components, and operating room equipment

The Estes Difference

Estes is different from many other medical device manufacturers, which is why so many leading medical technology companies choose to work with us. The Estes difference includes:

Creative, Innovative Thinking – The Estes prototyping team is a core group of engineers and designers who challenge modern methods and are committed to solving problems. Our team is focused on reducing lead times and finding cost-effective solutions for our customers.

State-of-the-Art Technology – Estes is committed to utilizing lean processes and the latest automated fabrication systems to ensure that our customers get precise, high-quality, best-in-class products.

Ability to Scale – Estes employs a staff of more than 100 associates, has 85,000 square feet of manufacturing space, and features a high level of capacity-multiplying automation to provide even the largest companies with on-time fulfillment services.

Trustworthy Team – For over four decades, Estes has been committed to hiring people of high character who are focused on delivering the highest level of service to medical OEMs.

PROCESS

01 | Design Input

We believe the best results come from collaboration. It all begins with asking the right questions and then listening closely. Once we understand exactly what you need out of the case, tray, or other type of medical equipment, we provide thoughtful solutions to solve your medical product design challenges.

02 | Conceptual Design

With a shared vision in place, we work closely with your engineering team to design concepts and create rough layouts of the product being produced. This allows us to collectively see the instrument placement and planned functionality before investing time in the details.

03 | Detailed Design

Our design team starts to pull it all together, ensuring each instrument will be secure during the rigors of use. Our goal here is to use as few components as possible in the medical equipment we design, which helps reduce cost, assembly time, potential assembly defects, and helps maximize sterilizability.

04 | Prototype

This is where the fun begins. We produce a fit and function prototype, allowing you to touch and test the product for instrument fit and to even perform sterilization validation testing. If any issues arise, we resolve them quickly before going into production.

05 | Manufacture

With Estes, you gain a one-stop shop that has been with the project since the onset. Specializing in light-gauge sheet metal fabrication, our Max Velocity automated sheet metal fabrication cell is one of the most cost-effective solutions OEM manufacturers use today.

Let Estes take your medical product design to the next level.

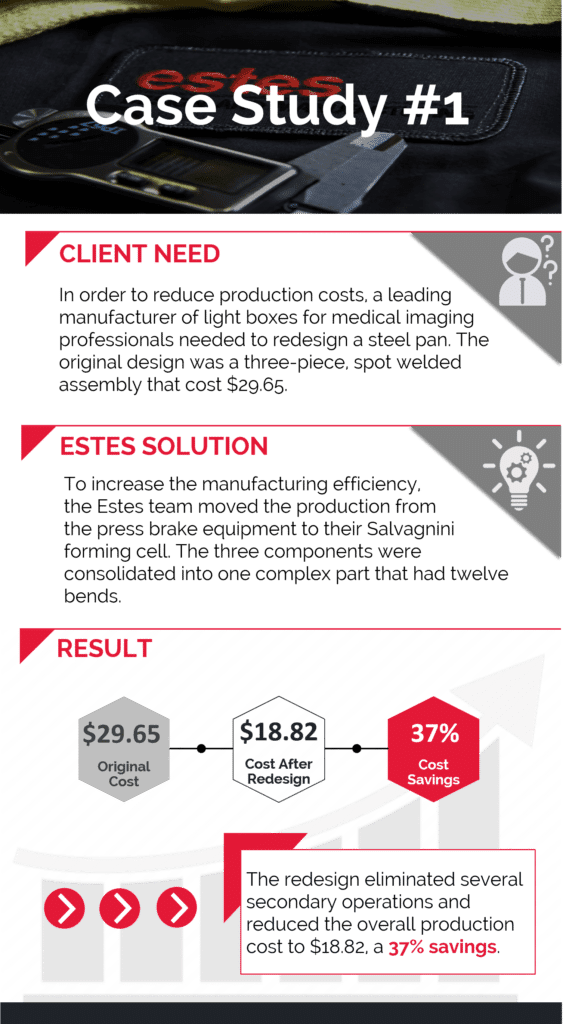

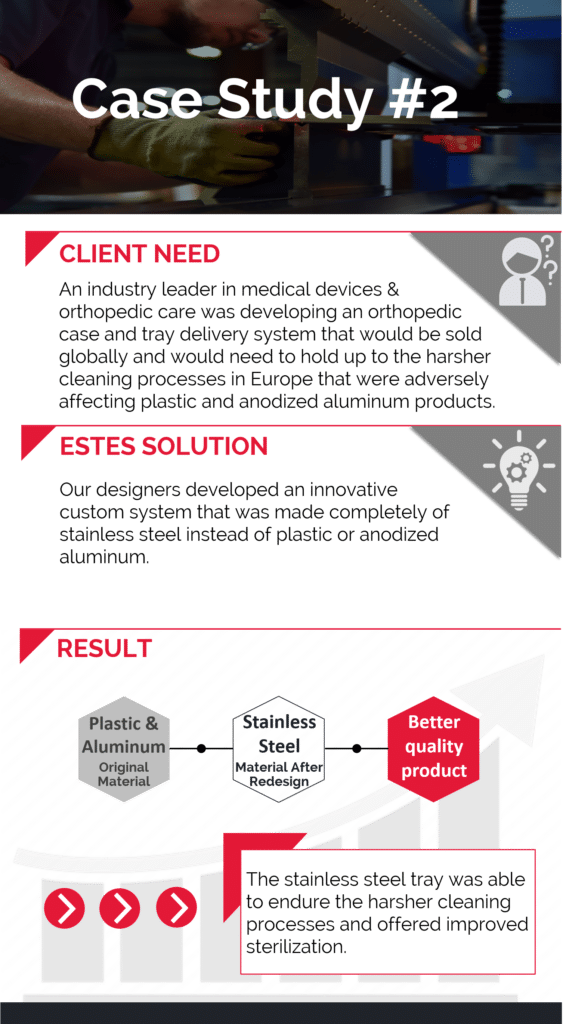

Case Studies

Medical Product Design Success Story

New Medical Prototype Revolutionizes X-Rays in Cath Labs

Dr. Babak Hassid, aka Dr. Bobby, approached Estes Design and Manufacturing with the concept and plans for an invention that could revolutionize the medical community, particularly cath lab doctors and support technicians.

Other sheet metal manufacturers told him they couldn’t do it; it wouldn’t work. Then he came to Estes, who listened and partnered with him. After six years of partnering together and multiple prototypes, Estes forged a relationship with this nationally and internationally recognized cardiologist and inventor. The outcome? The fourth iteration of ‘The Freedom Shield,’ now in the final validation phase, will revolutionize cath labs and become standard equipment for hospitals and medical centers.