Competition among manufacturers is stiff, and when you add in the current unpredictability we are facing, it becomes imperative that companies do everything possible to maintain their competitive advantage by focusing on their core competencies. One way to do this is by outsourcing processes, such as metal fabrication, that are not your primary business focus.

Successfully outsourcing your metal fabrication creates real value for your company by:

- Allowing you to focus on innovation

- Allowing you to provide enhanced capabilities

- Creating greater efficiencies

- Providing increased flexibility

All of these, in turn, lead to sustainable competitiveness within your industry.

Focus on Innovation

Unless you are a “me-too” provider that offers cheaper versions of products already on the market, your path to competitive success is through innovation of better products and new technologies. So it stands to reason that the bulk of your resources should be devoted to research and innovation rather than manufacturing.

Enhanced Capabilities

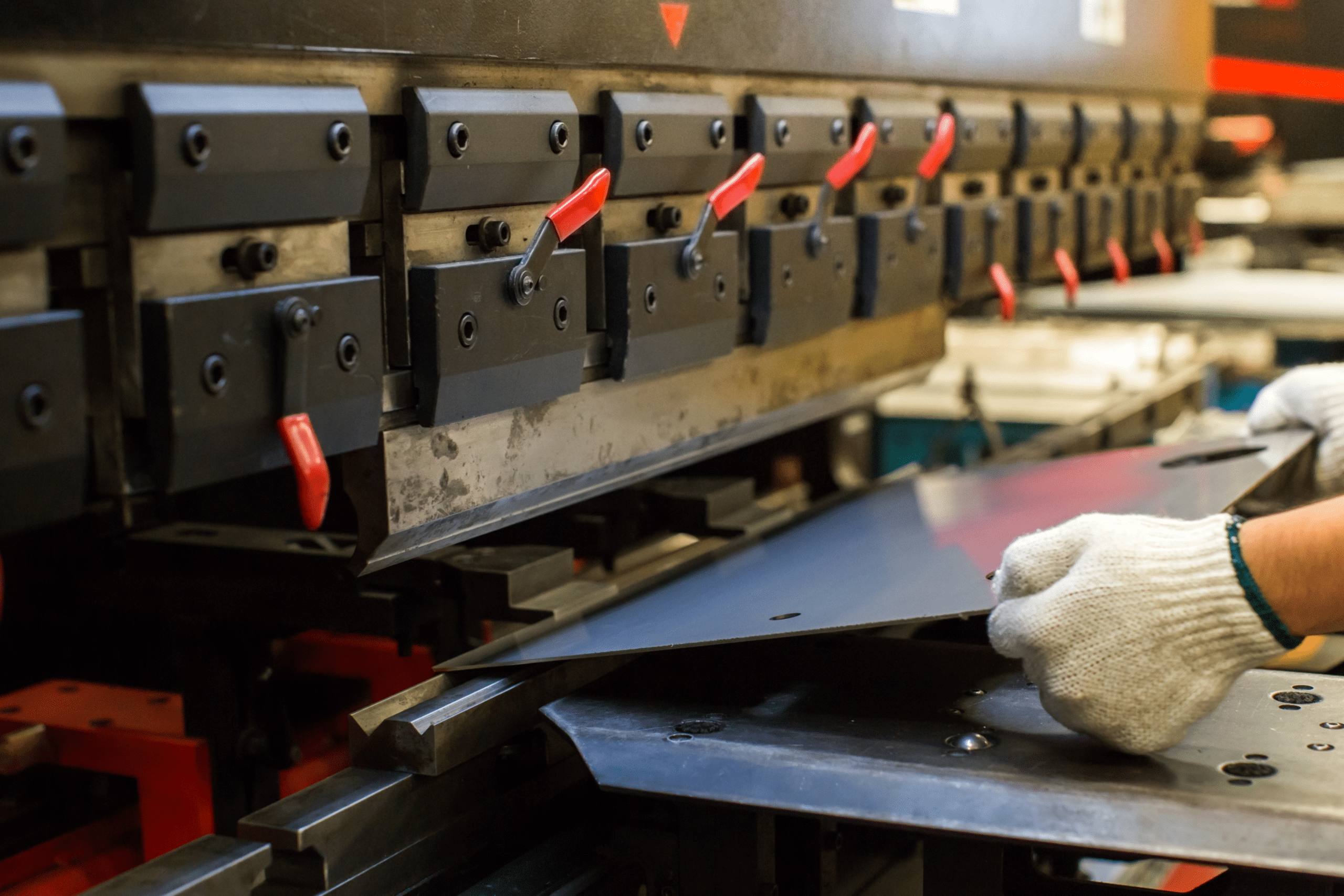

Technology is continually improving. If metal fabrication isn’t your core competency, staying current with equipment and processes can create a substantial financial burden on your company. A dedicated metal fabricator can more cost-effectively implement  the state-of-the-art-equipment that maximizes automation and provides enhanced accuracy and greater efficiency. This, in turn, allows you to supply your customers with higher-quality products at faster speeds and a reduced cost.

the state-of-the-art-equipment that maximizes automation and provides enhanced accuracy and greater efficiency. This, in turn, allows you to supply your customers with higher-quality products at faster speeds and a reduced cost.

Greater Efficiency

When you engage with a company specializing in metal fabrication, you are gaining their years of knowledge and expertise. A dedicated metal fabricator will understand the tricks of the trade required to apply DFMA (design for manufacturability and assembly) principles to your product designs. Those principles can result in more efficient bills of material and more efficient manufacturing processes. Additionally, if your metal fabricating partner provides prototyping services, your product development cycle can be more efficient—with faster prototype iterations and smoother transitions to full production.

Increased Flexibility

Outsourcing also gives you the flexibility to scale your operations up and down as your orders fluctuate. When demand increases, you don’t have to worry about investing in additional equipment or hiring more people. When demand decreases, you don’t have the burden of downsizing a workforce. The outsourced fabricator works as an extension of your company, working to meet your changing lead-time and delivery needs. If your metal fabricator offers an inventory management system, you will have the additional benefit of reduced lead-times and don’t have to store excess inventory. You can use the space that would otherwise be devoted to this inventory for revenue-generating activities.

Sheet Metal Fabrication at Estes Design and Manufacturing

Our clients are not just clients—they are partners. When you partner with us, our success depends on your success. With decades of experience and cutting-edge fabricating equipment, Estes offers a suite of services—including traditional metal fabrication, 3D laser welding, and product development and prototyping—to ensure your project is a success. Our lean manufacturing, automated cell technology, inventory management services, and cost reduction processes mean you see reduced lead-times, improved quality, competitive pricing, and consistent on-time delivery. When we take on your sheet metal prototyping or fabrication project, you can concentrate on innovation and increasing your market share, thus driving revenue growth for your company.

Contact us to get started!