You have your project plans, you’ve gathered quotes from metal fabricators, and now you’re ready to pick your new supplier. FabShop XYZ catches your eye…their estimate is much lower than the others. Great!

Actually, maybe not so great.

Cost is an important factor, and finding ways to reduce costs has never been more important as inflation continues to rise and impact almost every industry. However, when evaluating quotes for your sheet metal fabrication project, don’t make the common mistake of assuming the lowest quote will also give you the best value. You could be sacrificing far more important factors by going with the cheapest quote. There are several dangers with low-cost solutions, and the lowest quote may indeed be “too good to be true.”

Why Low Project Quotes Might be Dangerous

Hidden Costs

Hidden Costs

Some fabricators offer a low quote to attract customers, and then tack on service fees or other surcharges later in the project. Fabricators who are honest about their costs up front tend to be much more trustworthy. In addition to this, having a realistic picture of all project costs at the start of your project will help you ensure your project stays within budget and avoid long-term financial frustrations.

Low Quality Work

Low Quality Work

A fabricator could offer a low quote because they are a newer company trying to build a customer base, but that also means they are probably less skilled than a well-established, seasoned fabricator. Good, quality craftsmanship does not come at a low rate.

Cost savings could very well mean rushing through production, not taking the time to make sure the job is done right or not inspecting for quality along the way. This may get your project done faster, but the risk of poor quality or a very short lifespan also skyrockets. A cheaper up-front cost may mean greater rework costs or replacement parts down the road, increasing the overall project expense. Better to pay a bit more up front than incur more expenses later.

Like most other things, you get what you pay for in metal fabrication. If you want quality parts that will last, cheap is not the way to go.

Lack of Expertise

Lack of Expertise

You also want to make sure that the fabricator you’re choosing has the expertise to perform the tasks you need. For example, not all fabricators have design capabilities, so some will be incompetent if you need help with the initial plans. If you require more complex finishing processes, those might be out of some fabricators’ wheelhouse as well. Choosing a fabrication partner that can meet all your needs is crucial to the success of your project. Additionally, a more experienced fabricator may have worked on similar projects and be able to offer tips and advice to improve your product, as well as offer value-add services that will give you an advantage.

Not all fabricators are the same; each has its own set of machines and functions, skilled labor, and specialties. Before you even start considering cost, you want to find a fabricator that understands your specific needs and has the ability to meet them. Overconfidence is a major warning flag that may mean disappointment later.

Low Labor Costs

Low Labor Costs

Cheap quotes may mean that the fabricator runs its entire business cheaply: perhaps its employees are underpaid or its machines are not properly maintained. On the other hand, a fabricator who takes pride in its people and work and strives to maintain them will be far more likely to provide the quality work you are looking for. Again, quality work performed by experienced workers is often not found in the cheapest quote.

Cheap Raw Materials

Cheap Raw Materials

Not all metal is created equally. You want raw materials that will set your project up for success, not run the risk of breaking down when you need them most. Especially in current market conditions, raw material costs are being affected by inflation and other factors that will directly impact quote prices. A strong fabricator will only use good quality materials, which generally means an increase in price but also an increase in value. They will be very familiar with the different grades of metal and their proper applications, and therefore be able to recommend the best materials for your specific project application.

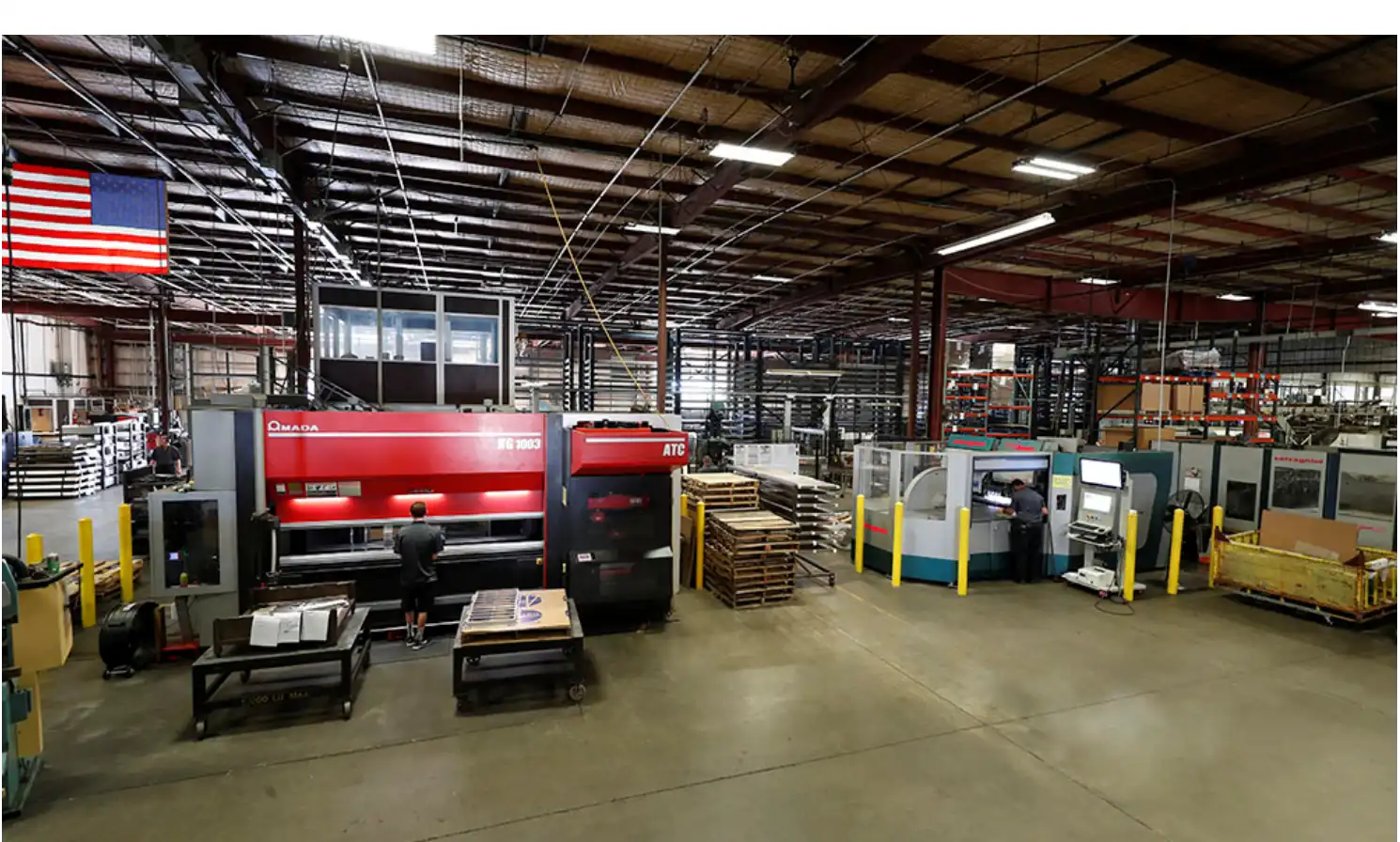

Let Estes be the Solution for Your Sheet Metal Fabrication Project

With decades of experience and cutting-edge fabricating equipment, Estes offers a suite of services, including product development and prototyping, 3D laser welding, and sheet metal fabrication, to ensure your project is a success. Our lean manufacturing and automated cell technology provides you reduced lead-times, improved quality, competitive pricing and consistent on-time delivery.

We take pride in our people, our processes, and the quality of our work, and we won’t sacrifice that. We strive to deliver the best customer value possible, and we believe that is worth every penny. Our clients are not just clients—they are partners. When you partner with us, our success depends on your success.

However, we also take pride in our cost-optimizing processes, saving you rework and replacement expenses. You can know your project will be well executed from beginning to end. Contact us today to see how we can help get your sheet metal fabrication project started!